Description

OUR MOST VERSATILE FILAMENT EXTRUDER

We have designed the PRO 1000 EX to be a safe, powerful, feature rich polymer extruder for your desktop. You can use it to quickly produce filament for your 3D printer with minimal setup.

- Produce filament in your favourite diameters, 1.75mm, 2.85mm or 3mm.

- Create custom colours and blends.

- Create filament when you need it anytime.

- Produce experimental and new materials.

Large Hopper Included

Some of the compatible materials*:

- PLA

- ABS

- LDPE

- HDPE

- PP

- EVA

- HIPS

- WAX

- TPU

- TPE

- PA6

- PETG

- Engineering Materials

*Each machine has been designed to be robust and to process a substantial amount of different materials. We assume that operators of extrusion equipment have sufficient experience however. If you need any assistance we invite you to contact us to discuss or speak with your material expert. Extrude safely!

-

350W HIGH POWER DC GEAR MOTOR

A powerful fan cooled DC motor connects directly to a 120mm gearbox delivering constant power to the extrusion screw. The speed is fully adjustable and delivers power to the motor via a robust dedicated MOSFET motor driver.

-

5 HEATERS OVER 4 ZONES

4 independent heat zones controlled via PID controllers with individual fans keep each heat zone at the precise temperature.

-

DEDICATED NOZZLE HEATER

Providing absolute control over the extrusion temperature right up to the nozzle ensures the best filament.

-

SPEED ADJUSTABLE SCREW WITH POWER STABILISER

A control on the front panel precisely adjusts the screw speed and with dedicated direct current power conversion electronics to maintain the precise motor control Voltage regardless of external power demands delivering a constant predictable screw speed.

-

SAFE & EASY OPERATION

Safety has been designed in from the ground up, specially designed hopper block limits access to anything except polymers, emergency stop button, non-latching controls meaning the machine will not automatically restart in the event of a power cut. One button control and interlocked motor to heater buttons means you can start extruding quickly with minimal setup.

-

QUICK SETUP

We include nozzles and a country specific power cable so you can start extruding right away.

-

UNIVERSAL VOLTAGE WORLDWIDE OPERATION

We have designed every extruder to be compatible with standard domestic electricity supplies. Operation from 120V to 240V, 50/60Hz.

-

EXTRUDE A MULTITUDE OF MATERIALS

We provide the extruder, the materials are up to you…

FilaFab has been developed as a tool to help you extrude a range of materials from standard readily available types to new compounds and other inventive materials. FilaFab machines have enabled entire new processes and business models. Used extensively in materials laboratories and for research and development new material applications have been directly developed using the FilaFab eco system. The portability, low cost of ownership and rapid deployment of the system has also enabled disruptive projects to be realised. Each machine has been designed to be robust and to process a substantial amount of different materials. We assume that operators of extrusion equipment have sufficient experience. If you need any assistance we invite you to contact us to discuss.

INTUITIVE SMART CONTROLS

-

Non-latching Controls – provides graceful power on/off with push button, critically the system will not restart automatically after power failure.

-

Real-time motor current monitoring and display with active shutdown – if a jam occurs and excessive current is pulled the monitoring system will switch the motor off. Part of a 3 layer motor power protection system.

-

Thermal fuses protect all sub-systems and can be reset directly from front panel.

-

Emergency stop is included across the entire extruder range to immediately bring the extruder to a stop when needed.

-

The screw access in the hopper features either a finger guard or designed so fingers can’t reach moving parts.

-

Emergency Stop Button

-

Alarm in case of control failure.

-

Robust steel enclosure protecting from touching and moving parts.

-

Over pressure protection.

-

Key switch lockout (PRO 1200 EX model only).

PRECISION BAND HEATERS

-

High quality mineral insulated band heaters.

-

Highest Watt densities.

-

Designed specifically for use with engineering-grade materials.

-

Incorporating quick change connector for ease.

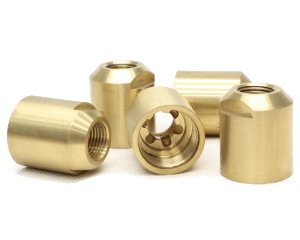

The nozzle system has been meticulously designed and produced to our extremely high specification. After machining the nozzle undergoes a final reaming stage which gives the nozzle a high tolerance round profile.

-

WARRANTY & NOTICE

Not to worry we offer a 1-year return to base parts warranty on all machines (please read exclusions).

3 months on band heaters since these are considered consumable.

Exclusions

Nozzles are not included in the warranty.

Damage due to over exertion/misuse, we are happy to repair this for you but this will not be covered by the warranty and will be billable.

What’s in the Box:

- Extruder

- Nozzle Adapter

- Hopper Assembly

- 2 Pack Nozzles (1.75 & 2.85 mm)

- Power Cable (with your country plug)

- Instruction Manual

GET THE WHOLE SYSTEM

Select Complete System from the product page to receive the extruder along with all the accessories to create an entire filament extrusion and winding line. This includes a discount for purchasing the entire system.

Kit includes:

- Extruder

- Spool Winder

- Diameter Control Module

- FilaPull Haul-off Module

- Fan Cooling Station

- All Power Supplies, Cables, Nozzles & Peripherals Required.

Reviews

There are no reviews yet.