PRO 350/200 EX

The PRO 350/200 EX is the most popular filament extruder with a new completely overhauled design and updated to version Mk7. Many new features including over rated heavy duty motor MOSFET driver and nitride hardened multi-stage screw.

PRO 1000 EX

The PRO 1000 EX is the latest and most feature rich desktop filament extruder. Providing the ability to extrude a huge amount of different materials. Integrated breaker plate ensures optimum pressure and filament precision.

Discounts for Education and Research

PRECISION ENGINEERING

EACH FILAMENT EXTRUDER IS PROUDLY DESIGNED & BUILT IN THE UK

The FilaFab Filament Extruder range encompasses our design ethos – quality and fit for purpose. Fabricated from precision engineered components to our exacting specifications. Take our range of screws which have been precision ground and nitride hardened to provide performance while maintaining a manageable desktop form factor.

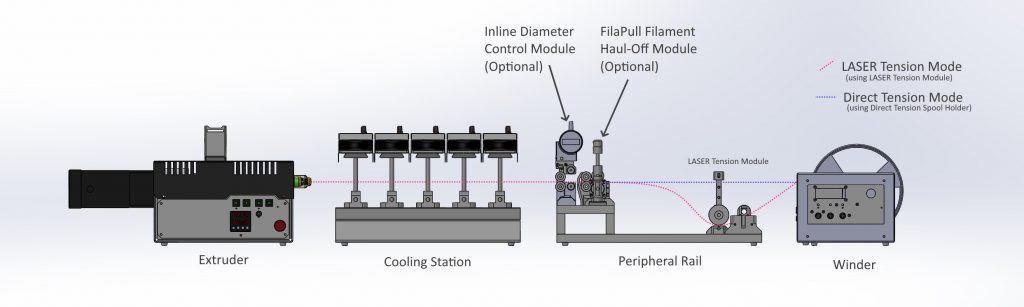

COMPLETE FILAMENT PRODUCTION LINE

Filament handling post extrusion can make a big difference to the quality of your filament which is why we have designed the peripheral system to be both configurable and customisable. Using selective 3D printed parts means they can be customised to suit your own needs, all files are available for your use. FilaFab is the ultimate desktop filament extrusion ecosystem.

- Multiple operating modes to support your requirements.

- Supports most spool sizes with the universal mandrel or 3D print your own adapter.

- Full range of accessories.

- Adjustable layering/spooling speed.

- Automatic/manual operation.

THE COMPLETE FILAMENT EXTRUDER AND SPOOLING LINE FOR YOUR DESKTOP

VISIT OUR E-SHOP

OR EMAIL info@filafab.co.uk

Sign up to our newsletter

We have been busy and have lots of news to share… be the first to hear about it.

Need a Quotation in a hurry? Email us now!

Or try our simple quote creator – hit BUILD QUOTE or create from Basket

WHY CHOOSE FILAFAB EXTRUDERS

Used across multiple industries for diverse applications from the development of new compounds to bespoke on demand materials. Our extrusion systems have been used in cutting edge research and can be found in materials labs across the world.

ENDLESS RECYCLING POSIBILITIES

FilaFab can be used to recycle a vast array of plastics, new processes are being continually created from recycling failed 3D prints to producing entire local plastic waste collection and repurpose eco systems. FilaFab can be setup quickly on location to provide instant results with minimal waste material transportation.

DRAMATICALLY LOWER COST

By producing the exact filament you need when you need it big cost savings can be made. Expensive materials can be produced in the quantity required from raw materials which are significantly lower in cost. Extremely high cost filaments can also be produced in miniature volumes.

AHEAD OF THE COMPETITION

FilaFab has been used in labs across the world to create new materials and is used extensively in scientific research. Our extruders provide several advantages over traditional extrusion systems and are used not only within the additive manufacturing sector but also across a broad range of industries including enabling new business processes to be capitalised on.

WELCOME TO OUR FILAMENT EXTRUDER WEBSITE. PROUDLY EXTRUDING SINCE 2013!

DISCOUNTS FOR EDUCATIONAL INSTITUTES

GLOBAL SHIPPING

BULK ORDERS & FLEXIBLE INVOICING

About Us

With R&D at our core we built our first prototype in 2012 and since then have continued developing our extrusion systems. Today we have 4 filament extruder systems and complete spool winding accessory systems. Our flagship products are now on the 7th generation design.

Our mission is to lower the cost of 3D printing, enable recycling systems and empower our users to create revolutionary new materials and processes.

Our Journey (brief version)

2014 – launched the first desktop filament extruder in the UK.

2016 – Redesigned and released PRO 100/350 EX series.

2017 – Spool Winder launched.

2018 – Cooling Station and Inline Diameter Control introduced

2019 – Complete product line revamp and upgrade

2020 – Released PRO 1200 EX

2021 – Released PRO 1000 EX and major product redesign and re-launch.

2022 – New website launched showcasing current products

2022 – and beyond – NEW products coming soon!